Built for precision

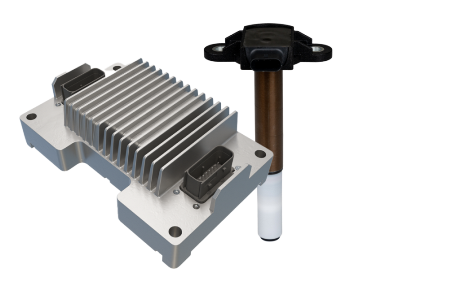

Phinia develops and manufactures

inductive and contact-free linear position sensors designed to work reliably in

the most demanding environments.

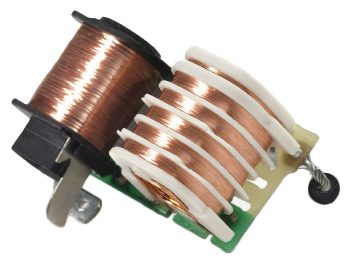

This product area delivers precise

linear measurement solutions based on inductive technology. Inductive sensors

are easily adapted to various applications such as clutch and brake wear, gear

position indication and measurement of liquid levels.

Designed and manufactured to meet

the automotive industry’s extensive requirements for diverse vehicle

applications.

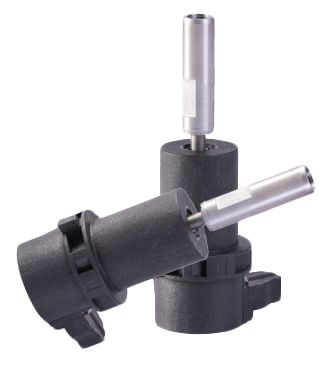

The linear position sensor is an

essential component in automated manual transmissions (AMT) used in heavy

trucks. The AMT is a known and proven contributor to reduced fuel consumption

by optimizing the timing and shifting of gears. Removing the need for manual

interaction from the truckdriver enhances and simplifies the work environment

and increases road safety by minimizing distractions.

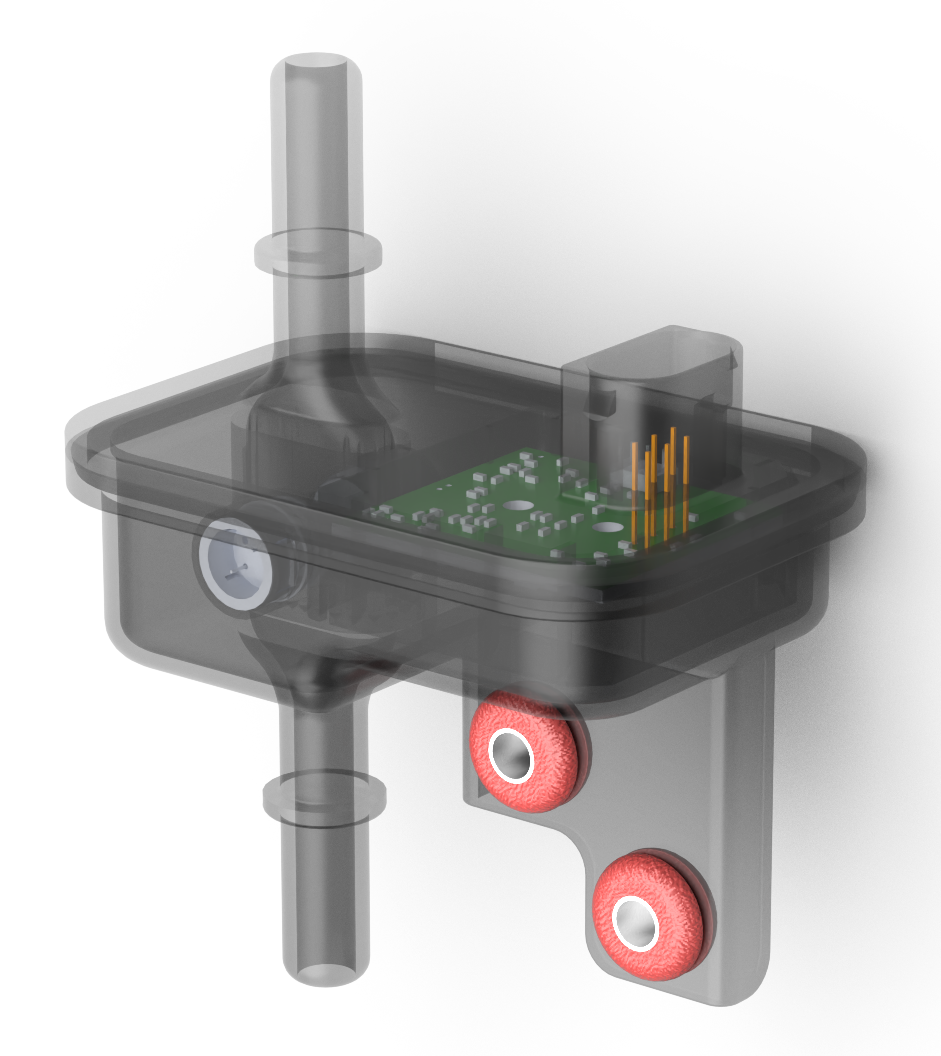

The sensors are fully contact-free,

reliable, highly accurate, and have a long and proven history in gearbox

solutions produced by leading commercial vehicle OEMs. All products are offered

fully tailored to the specific requirements of each application, with adaptable

housing geometry, stroke length and mating parts. They can be fitted with

either a molded cable or an integrated connector.